Horwood Bagshaw laser buckets, also known as Alfarm laser buckets, perform many functions improving land used for food production and efficient use of our precious water resources. The Horwood Bagshaw laser bucket has various applications, such as ripping, levelling, forming, trenching and grading.

Horwood Bagshaw laser buckets have been at the forefront of efficient land levelling ripping and soil management for over two decades. With a cutting-edge design incorporating advanced laser technology, these buckets have revolutionized how farmers approach soil preparation. Since their introduction, Horwood Bagshaw machines have become an indispensable tool for farmers throughout Australia, allowing them to rip through tough soils with ease while minimizing water usage and maximizing crop yield. In this article, we will explore the history and development of the Horwood Bagshaw / Alfarm laser buckets and how they have helped farmers achieve greater efficiency and productivity in their operations.

Laser buckets are a tool used in modern irrigation technology that has revolutionized how land is formed for efficient water use. With the help of laser buckets, farmers can level their land with precision, ensuring that water is distributed evenly across the field. This technology uses a laser-guided bucket cutting edge system to create a level surface, allowing for uniform water distribution and efficient irrigation water use.

Using laser buckets, farmers save precious resources and cut costs associated with water usage. This technology is particularly useful in arid regions where water is scarce and needs to be used judiciously. Overall, laser buckets are helping farmers to optimize their irrigation practices and produce more food with less water.

Horwood Bagshaw buckets, also known as the Horward Bagshaw/Alfarm Laser Bucket, are proudly made in Australia, with a  commitment to quality and reliability that is unmatched. The company has been manufacturing agricultural equipment in Australia for over 150 years and is dedicated to supporting local communities and the Australian economy.

commitment to quality and reliability that is unmatched. The company has been manufacturing agricultural equipment in Australia for over 150 years and is dedicated to supporting local communities and the Australian economy.

By sourcing materials locally and employing skilled workers, Horwood Bagshaw ensures that their products are not only of the highest quality but also support the growth of local industries. This commitment to research and development ensures that Horwood Bagshaw remains at the forefront of the agricultural equipment industry in Australia.

Horwood Bagshaw's dedication to producing high-quality products made in Australia has earned them a reputation as a trusted and reliable supplier of agricultural equipment.

The owner of Horwood Bagshaw is Peter Horwood, who founded the company in 1862. The company has been family-owned and operated for over 150 years and was owned by the three generations of the Horwood family. In 2018 the company was acquired by CNH Industrial, a global agricultural equipment manufacturer.

Alternative 1: Collier and Miller's Scraper

Collier and Miller's Scraper is a high-quality alternative to Horwood Bagshaw's laser buckets. The scraper is designed to be durable and reliable, featuring a heavy-duty bucket construction and robust frame. Laser bucket operators had input into designing the Collier and Miller Scraper for operators making it perfect for various applications, including earthmoving, land clearing, and levelling.

The scraper is available in various sizes to suit different needs and is highly recommended for farmers and contractors who need to move large amounts of soil quickly and efficiently.

Alternative 2: JNR Scraper

Another alternative to Horwood Bagshaw's laser bucket is the Hodgco JNR Scraper. This scraper is designed to be easy to use and highly maneuverable, perfect for smaller jobs and tight spaces. The JNR Scraper is built to last, featuring a heavy-duty frame and durable construction. The scraper is highly recommended for farmers and contractors who need a reliable and efficient way to move soil and other materials.

Alternative 3: O'Bryan Scraper

The O'Bryan Scraper is another excellent alternative to Horwood Bagshaw's laser buckets. This scraper is designed to be highly versatile, featuring a range of different blades and attachments that can be used for various tasks. The O'Bryan Scraper is perfect for levelling, grading, and earthmoving. It is highly recommended for farmers, contractors and the equipment rental business, who need a versatile and reliable tool for their work. The scraper is available in various sizes and configurations to suit different needs.

Other brands include the Toomey Scraper and the HODGCO Laser buckets.

When operating, repairing or maintaining heavy machinery, it's essential to understand the difference between replacement parts and spare parts, especially when assessing warranty. Spare parts refer to components used to replace worn-out or damaged parts in machinery; however, replacement parts refer to parts consumed through the normal operation of your equipment.

Replacement parts include cutting edges, ripper points, bucket skirts and ripper points, whereas bearings, pins, bushes and hydraulic cylinders would be considered spare parts. Replacement parts are manufactured to the same specifications as the OEM parts and are designed to perform the same functions. In some cases, there are improved none, genuine parts designed to reduce downtime and improve performance.

Replacement parts are usually readily available from manufacturers or suppliers, while spare parts may need to be ordered in advance. Unfortunately, the differences between quality replacement wear parts and lubricants are not always visible so working with a trusted, reliable supplier of replacement wear parts with experience in the laser bucket industry is key to reducing overheads and streamlining contractor operations.

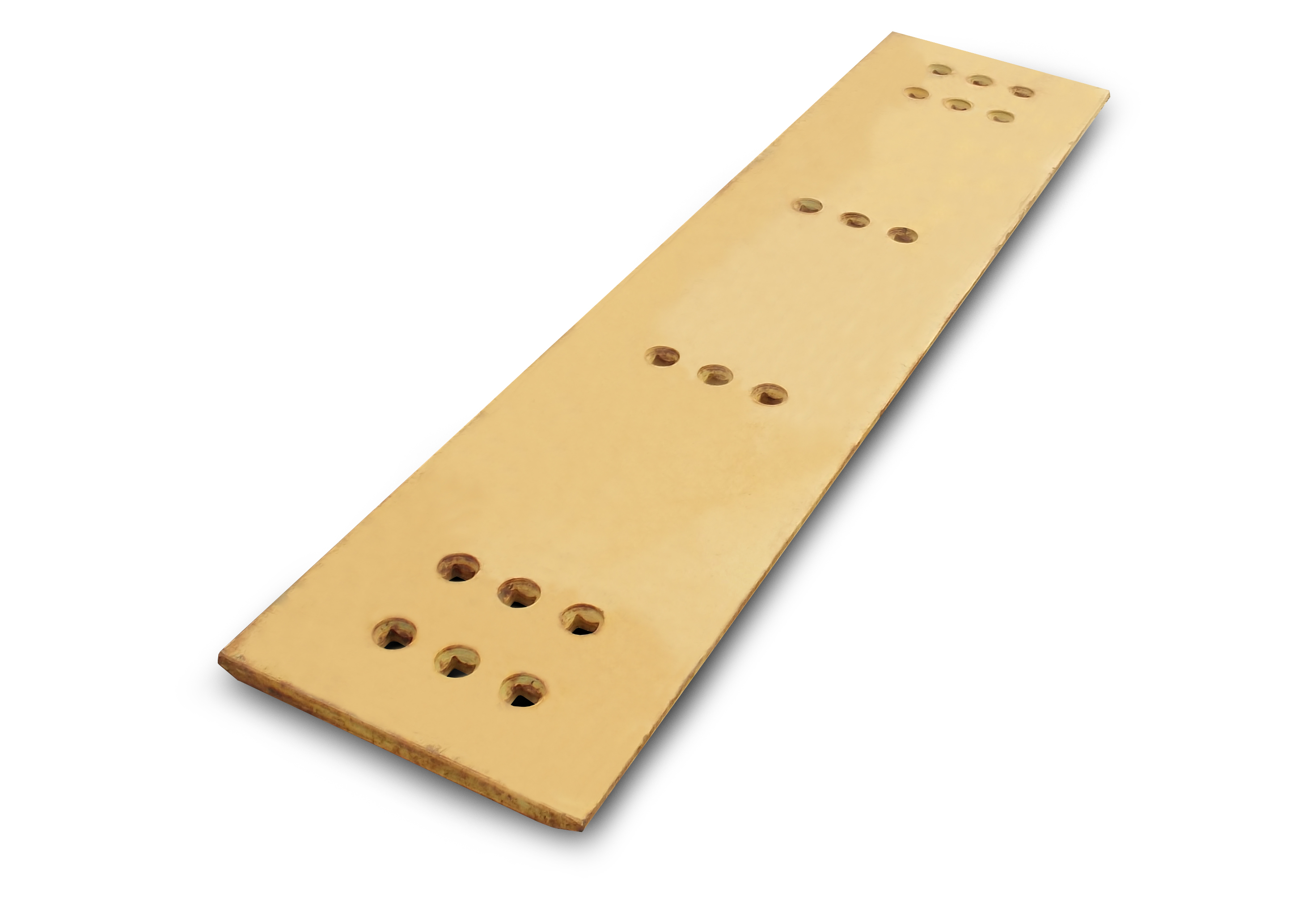

The Horwood Bagshaw laser edges are highly versatile and perfect for various applications. Ensuring that each edge wears perfectly straight with a sharp edge allows for clean, efficient and precise cuts every time. The design is also incredibly durable, thanks to its high-quality materials and construction, making it suitable for use in even the toughest Australian environments.

The Horwood Bagshaw laser edges are highly versatile and perfect for various applications. Ensuring that each edge wears perfectly straight with a sharp edge allows for clean, efficient and precise cuts every time. The design is also incredibly durable, thanks to its high-quality materials and construction, making it suitable for use in even the toughest Australian environments.

Additionally, the design is compatible with a wide range of buckets. With two different edge lengths, 4' and 5' long, they can be used in various combinations to fit all bucket widths in the fleet. This ensures operators in remote areas don't have to carry a large stock of replacement bucket cutting edges, yet they can rest easy that downtime will be minimum as they have the right part at the right time. Overall, the Horwood Laser Bucket Edge design is an excellent choice for anyone looking for a versatile and reliable cutting edge solution and has been copied across other makes, like the Hodgco and O'Bryan scraper buckets with some small variations.

Laser bucket cutting edges have been around for some time now and have proven to be an effective solution for cutting through tough materials. However, there is always room for improvement, and manufacturers are continuously working on new ways to enhance the performance of these cutting edges.

One area where improvements are being made is in the design of the cutting edges. New geometries are being developed that offer better cutting performance and longer life. These new designs are optimized to reduce wear and tear on the cutting edge, reducing the need for frequent replacements. One such improvement was increasing the edge width from 280mm to 305mm wide. This increases the wear material by 15% with no extra hole costs.

Another area where improvements are being made is the material used to make the cutting edges. Manufacturers are experimenting with new alloys which increase the hardness while resisting breakage and coatings like TERRATUF, which offer better wear resistance and longer life when applied correctly in the correct position. Some new materials can withstand extreme temperatures and harsh environments, making them ideal for cutting through tough materials such as steel and concrete.TERRATUF coating also improves efficiency by maintaining a sharper edge

Making laser bucket ripper points last longer and cost less

Making laser bucket ripper points last longer and cost lessRipper points are a key component of laser buckets, used to break up hard materials and provide efficient excavation. Over time, however, the wear and tear on ripper points mean they must be replaced regularly.

Fortunately, there are ways to prolong the life of ripper points and reduce replacement costs. Points are cast using a wear-resistant alloy which can be enhanced using TERRATUF coating. In some cases, ripper points on scrappers using TERRATUF technology have proven to last more than four times longer than the uncoated bucket teeth.

Texxon XHD Red grease is a high-performance lubricant for heavy-duty, reliable machines such as laser and scraper buckets. This grease is  designed to provide superior protection in high-temperature / dusty conditions and extend the lifespan of machinery components, including pins, bearings, and apron rollers.

designed to provide superior protection in high-temperature / dusty conditions and extend the lifespan of machinery components, including pins, bearings, and apron rollers.

When used on scraper bucket spare parts, Texxon XHD Red lithium grease, which uses the latest semi-synthetic grease technology, helps to reduce friction and wear between moving parts. This is particularly important for pins and bearings, which are subject to much stress and strain during operation. By reducing friction, Texxon XHD Red Grease prevents premature wear and tear from impacts and contamination, which can lead to costly repairs and downtime.

More profits and less downtime are key to a successful, fast, growing business. TERRA edges and ripper points with TERRATUF coating will maximize profits and minimize downtime. It is essential to invest in the right components and technology for your machinery. Advanced bucket cutting edges, high-performance lubricants, and wear-resistant ripper points can make all the difference in getting the job done quickly and efficiently.

By investing in improved cutting edges, lubricants and wear-resistant parts, businesses will reduce replacement costs and increase profitability.